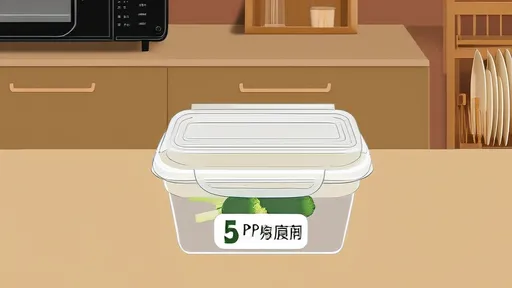

In the bustling aisles of modern supermarkets and the organized chaos of our own kitchens, a quiet revolution has taken place. The humble plastic food container, once a simple vessel for leftovers, has evolved into a sophisticated tool for convenience. Yet, this convenience is often shrouded in a fog of confusion and misinformation. A quick glance at the bottom of any container reveals a cryptic numerical code, a hieroglyphic to the uninitiated, holding the key to its safe usage. Among these symbols, one stands out as a beacon of safety for the microwave era: the number 5, encircled by chasing arrows, signifying the material known as polypropylene, or PP.

The story of plastic identification is not one of mere corporate branding but a crucial public health initiative. The Resin Identification Code (RIC) system, developed by the Society of the Plastics Industry (SPI) in 1988, was never intended to be a guarantee of recyclability, though it is often mistaken for one. Its primary purpose was to provide a consistent, national system to facilitate the sorting and recycling of post-consumer plastics. However, for the discerning consumer, these numbers have taken on a far more immediate meaning: they are a quick-reference guide to safety, especially when heat is involved. The triangle of arrows, often misinterpreted as a universal recycling symbol, simply houses a number that tells you what you're holding. It is a first step, not a final answer.

This is where Polypropylene, or PP, enters the spotlight. Designated by the number 5, this polymer is a workhorse of the plastic world. Its molecular structure is a key to its superpowers; it has a high melting point, typically around 160°C (320°F). This inherent thermal resilience is what makes it the prime candidate for containers destined to face the intense energy of a microwave oven. Unlike its cousin polyethylene terephthalate (PET, #1), which might warp or leach chemicals when heated, or polystyrene (PS, #6), which can break down, PP remains stable. It doesn't soften, distort, or release its constituents into your food under normal microwave heating conditions. This stability is why you find it not just in your Tupperware, but in medical devices, automotive parts, and yogurt containers—applications where reliability under stress is non-negotiable.

So, what does "microwave safe" truly mean? The term itself, while useful, can be misleading. It is not a government-mandated certification but a performance claim made by manufacturers. Generally, it implies that the container has been designed and tested to withstand microwave temperatures without melting, warping, or leaching chemicals in amounts that exceed strict regulatory standards. The presence of the PP #5 symbol is the most reliable consumer-facing indicator of this property. When you see that number, you are looking at a material whose fundamental chemistry is aligned with the application of heat. It is the difference between a material that merely survives the microwave and one that is engineered for it.

However, the presence of the #5 is not a blanket invitation for reckless heating. Safety is a partnership between the product's design and the user's practice. A crucial caveat often overlooked is the container's lid. Many containers feature a multi-material design; the base might be sturdy PP #5, but the lid could be made from a different plastic, like polyethylene (#2 or #4), or feature a seal made of silicone or other elastomers. These components often have different thermal properties. A lid not rated for microwave use can melt, warp, or leach chemicals, contaminating the food it's meant to cover. The universal rule of thumb is simple: when microwaving, always remove the lid or at the very least, ensure it is explicitly labeled as microwave-safe alongside the base. Venting the container by leaving the lid ajar or using a microwave-safe cover like a paper towel is also critical to prevent dangerous pressure build-up from steam.

Beyond the lid, other best practices ensure that your convenient meal remains a safe one. Avoid microwaving fatty or oily foods in any plastic container for extended periods, as high-fat content can attract more potential migrants from the plastic and also reach higher temperatures than water-based foods. Never use old, scratched, or damaged containers. Scratches can harbor bacteria and, more importantly, can degrade the plastic's integrity, creating points where chemical leaching is more likely to occur. And perhaps most importantly, always follow the manufacturer's instructions. They have tested their specific product formulation and design and provide the most accurate guidance for use.

The conversation about #5 PP would be incomplete without addressing the broader, and often heated, debate surrounding plastics and health. Concerns about endocrine disruptors like Bisphenol A (BPA) have made consumers justifiably wary of all plastics. It is vital to know that polypropylene is generally considered a safer alternative in this regard. It is not manufactured using BPA or phthalates, the plasticizers often of concern in other plastics like polycarbonate (which is #7, a catch-all category). The FDA regulates all food-contact materials, including plastics, and evaluates the potential for substances to migrate into food. PP has a strong track record under this scrutiny. However, science is iterative. Ongoing research continues to examine the long-term effects of all food contact materials, and a cautious approach is always wise.

Finally, the life of a PP container doesn't end at the microwave. Its recyclability is a common point of confusion. While the #5 symbol identifies the resin type for sorting, whether it actually gets recycled depends entirely on the capabilities and market demands of your local municipal recycling program. Many communities do accept #5 plastics, but many others do not, a victim of fluctuating economic markets for recycled materials. The onus is on the consumer to check with their local waste management authority to understand what is accepted. This step is crucial because "wish-cycling"—tossing non-recyclable items into the bin in the hope they will be recycled—can contaminate entire batches of otherwise recyclable materials, doing more harm than good.

In conclusion, navigating the world of food storage need not be a daunting task filled with anxiety. Empowerment comes from knowledge. By simply turning a container over and looking for the stamped numeral 5 inside the triangular arrow symbol, you can make an informed decision that prioritizes both convenience and health. The polypropylene container is a testament to smart material science, offering a durable and heat-resistant option for our fast-paced lives. But remember, this power comes with responsibility—to handle it correctly, to heed warnings about lids and damage, and to ultimately dispose of it thoughtfully. In the simple act of checking a number, you are not just reheating lunch; you are making a conscious choice for safety and sustainability.

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025