In an era where energy conservation and sustainable living are at the forefront of global conversations, innovative yet simple practices are gaining traction. One such method, leveraging residual oven heat to cook sweet potatoes after turning off the appliance, has emerged as a surprisingly effective way to cut electricity usage by up to 30%. This technique not only aligns with eco-friendly goals but also offers practical benefits for households looking to reduce their energy bills without sacrificing culinary enjoyment.

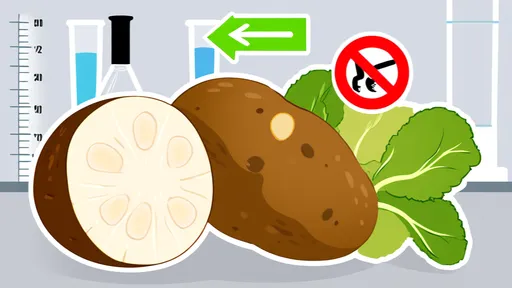

The concept is straightforward: instead of allowing the accumulated heat in an oven to go to waste after baking or roasting, users can utilize this residual thermal energy to prepare additional dishes. Sweet potatoes, with their dense texture and need for prolonged cooking, are ideal candidates for this method. By placing them in the oven immediately after switching it off, the retained heat continues to cook the tubers thoroughly, resulting in perfectly tender and caramelized outcomes. This approach eliminates the need to keep the oven running for an extended period, directly translating to significant energy savings.

From a scientific perspective, ovens, especially electric ones, are designed to retain heat efficiently due to their insulated construction. After being turned off, the internal temperature drops gradually, often remaining high enough to cook food for anywhere from 15 to 45 minutes, depending on the oven's model and initial temperature. Studies indicate that this residual heat can maintain temperatures above 300°F (150°C) for a considerable time, sufficient to complete the cooking process for many foods, particularly root vegetables like sweet potatoes. By capitalizing on this phenomenon, households can achieve a 30% reduction in energy consumption for oven-related tasks, as the active heating element is engaged for a shorter duration.

Adopting this practice requires minimal effort but offers substantial rewards. For instance, if a family bakes sweet potatoes twice a week using residual heat, they could save approximately 1.5 to 2 kilowatt-hours per month, depending on oven efficiency. Over a year, this accumulates to notable savings on electricity bills and a reduced carbon footprint. Moreover, this method dovetails with broader energy-efficient habits, such as batch cooking or using oven heat for multiple purposes, amplifying the environmental and economic benefits.

Beyond the immediate energy savings, this technique enhances the culinary experience. Sweet potatoes cooked in residual heat often have a superior texture and flavor profile. The gradual decrease in temperature allows for slow, even cooking, which helps develop natural sugars and prevents the exterior from burning. This results in a creamier interior and a subtly caramelized skin, making the dish more enjoyable without any extra effort or ingredients. It’s a win-win scenario where sustainability meets gastronomy.

While the focus here is on sweet potatoes, the principle can be applied to a variety of other foods. Items like roasted nuts, dried herbs, or even reheating leftovers can benefit from residual oven heat, further broadening its utility. The key is understanding the thermal properties of the oven and the cooking requirements of different foods. Experimentation may be needed to perfect timing and placement, but the learning curve is gentle, and the payoff is well worth it.

In conclusion, utilizing residual oven heat to cook sweet potatoes is a brilliant, accessible strategy for energy conservation. It underscores how small, intentional actions can collectively make a significant impact on resource usage and environmental preservation. As more households embrace such practices, the cumulative effect could contribute meaningfully to global sustainability efforts, all while enjoying delicious, home-cooked meals. This approach is a testament to the idea that innovation doesn’t always require complexity—sometimes, the simplest ideas are the most powerful.

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025

By /Aug 20, 2025